Our tool for managing your permission to our use of cookies is temporarily offline. Therefore some functionality is missing.

OF LASTING VALUE.

Recycling at BMW.

BMW establishes the basis for environmentally acceptable reuse while a new model is still passing through the development and production process.

By using recyclable synthetics, a reduced range of materials, and careful separation of different materials, BMW has ensured that vehicles can be recycled quickly and efficiently.

This concept has placed the BMW Group among the leaders on the Dow Jones Sustainability Group Index, the world's most important list of sustainability-oriented companies.

ENVIRONMENTALLY ACCEPTABLE REUSE.

New approaches to vehicle recycling: businesses which specialise in the recycling of end-of-life vehicles are involved. Every kilogram of scrap is processed in whatever way makes the most sense both ecologically and economically. Valuable raw materials are returned to the production cycle, reducing the burden on the environment. The controlled return, pre-treatment, disassembly and recycling of the residual vehicle are the four stages involved in dealing with end-of-life vehicles in an environmentally acceptable way.

Controlled collection

The vehicle recycling process starts with their controlled handover to a collection point or approved treatment facility. Only they are able to issue the confirmation of recycling that is often needed in order to register the vehicle officially as out of circulation.

Removal of operating fluids

In the pre-treatment stage, first of all the airbags and other pyrotechnical components are ignited. The recycling process proper starts with the removal of all operating fluids on a dedicated stand. This workbay is where e.g. the refrigerant from the air conditioning system and the brake fluid are extracted, the coolant, engine oil and transmission fluid drained off and the fuel pumped out using a special device. Each of the various fluids is decanted separately into storage containers and reconditioned at special plants or used as they are.

Disassembly

In future, by law 85 percent by weight of an end-of-life vehicle will have to be reused in the components’ current form or as a source of material for making new parts. That target has long since been achieved for metal parts. Glass and many plastics can already be recovered economically. The BMW Group has played a vital part in this process by pioneering new techniques. Expertly dismantled engines can be reconditioned and reused for their original purpose, as a form of high-end recycling.

Recycling of the residual vehicle

After disassembly, the residual vehicles are taken to a shredding plant. These facilities cut up the residual bodywork into pieces the size of your palm, and sort them. Plastics, textiles, iron and nonferrous metals are reused.

DESIGN FOR RECYCLING.

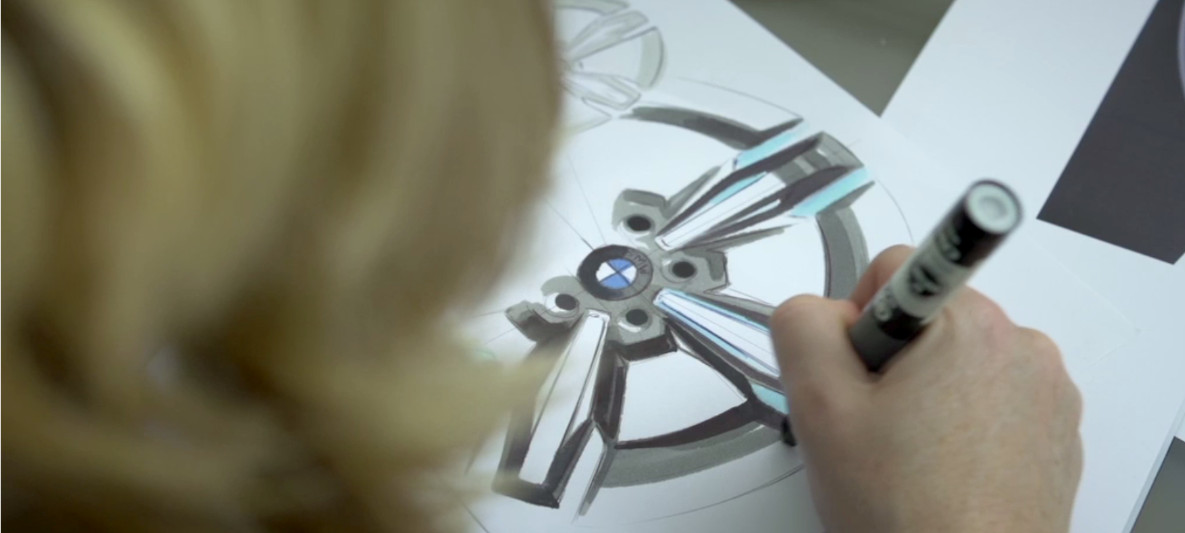

BMW’s Design for Recycling engineers set the tone for the recycling and disposal of end-of-life vehicles by defining efficiency and environmental acceptability as their priorities. Recycling is therefore an integral aspect of the product development process. Aspects that have a bearing on recycling, such as component design, the choice of materials and the joining techniques, can consequently be taken into account early on.

Another of their aims is to promote the use of recycled, quality-assured secondary materials in new vehicles. This paves the way for self-contained material cycles.

ALL SERVICES OF THE BMW GROUP

INTELLIGENT COMPONENTS WITH AN IN-BUILT NEW LEASE OF LIFE.

Measures for environmentally acceptable

• In the development phase, the design engineers assess the recyclability of all components and keep a record of their findings on the component drawing.

• Recycling concepts are prepared for large components such as the bumper trim, cockpit etc.

• In choosing the materials, efforts are made to reduce diversity and avoid non-recyclable materials.

• The use of intelligent joining techniques ensures that components can be sorted by material after disassembly.

• The environmental impact of components is systematically evaluated in “life cycle assessment” case studies.

• Virtual and physical disassembly analyses are carried out to ensure that every BMW vehicle achieves the defined targets.

• BMW shares the findings of its disassembly analyses with all economic operators involved in the recycling process, through training courses and detailed documentation.Efficient recycling of BMW vehicles

These measures ensure the following for all BMW vehicles:

• that pyrotechnical components such as airbags and belt tensioners can be fully ignited via a standard interface,

• that all operating fluids, in other words oils, fuel, coolant and brake fluid, air conditioning refrigerant, etc. can be removed swiftly and thoroughly through a designated drilling point or a drain hole,

• that plastic components weighing more than 200 grams bear a material designation,

• that large plastic components that lend themselves to economical recycling can be removed quickly and easily.

COLLECTION OF END-OF-LIFE VEHICLES.

As a result, the last holder or owner must hand their end-of-life vehicle over to a collector or other return point, or to an approved treatment facility. They will then be given the confirmation of cycling that they need to deregister their car with the authorities.

Return points operating on behalf of BMW take back registered end-of-life BMW vehicles free of charge. The following basic conditions must be met for vehicles to be taken back free of charge:

The end-of-life vehicle must be intact (and in particular have its engine, drive unit, body, catalytic converter, value-determining electronic components as well as other major components) and be free of waste.